Cardboard

We use cardboard material with the least environmental impact and minimizes waste generation.

Rigid

Rigid is highly protective, affordable and recyclable material. These boxes provide maximum protection.

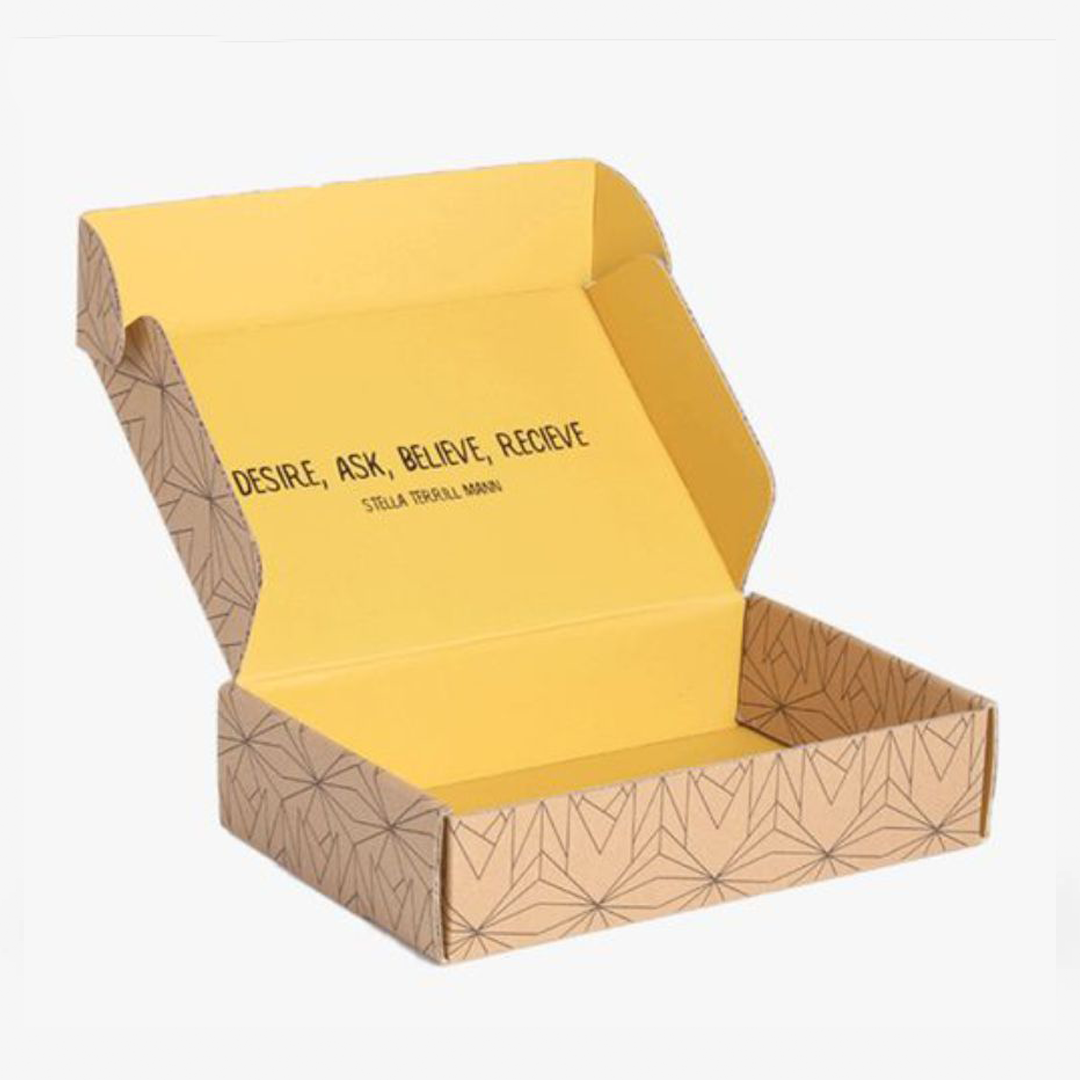

Corrugated

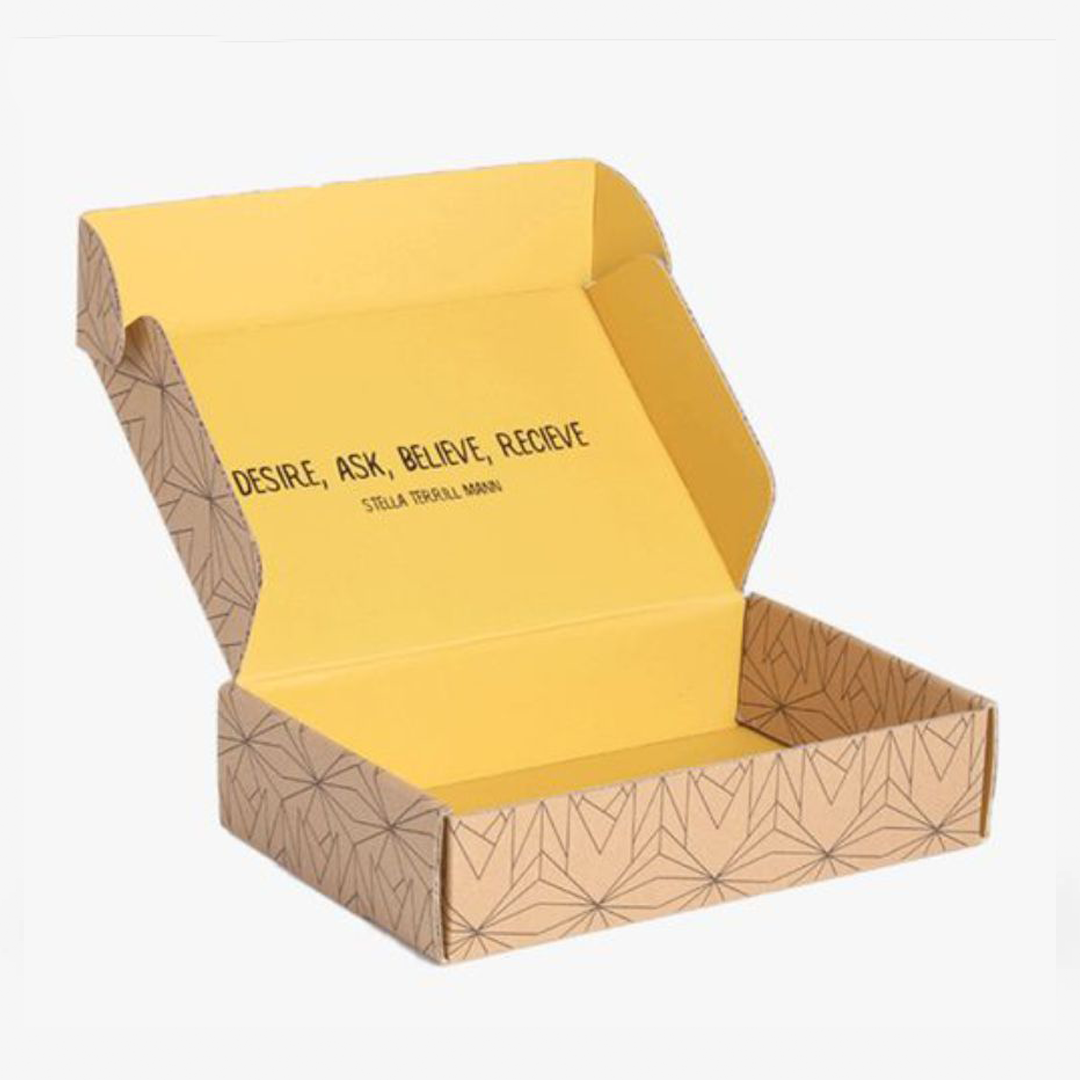

Corrugated material is easy to customize, cost effective and sustainable. It is also great for branding purposes.

Kraft

Kraft paper is a strong, durable and reliable material that is widely used across many different industries.

Description

Bottom Tray

These cardboard trays are good for transporting light loads and fragile items. That makes it one of the most favorite Bottom closure style boxes. Best suitable to provide durable protection to every type of object. These can be of anything from glass, plastic, or sensitive gift items. The structure of the closure type gives it the name as it suggests, there is a bottom tray having two-sided walls and a lid over it that makes it a layered bottom tray. The tray lands in the container that makes two parts of it. One is the container and the other is the lid. You can separate the lid more easily when you want to unpack your packaged material. These aspects make it a great choice for the transit of items that otherwise might get damaged during movement from one place to another. The main purpose is to provide support and assistance to the item inside. It will not move inside the box and will thus be safe from any sort of loss during movement.

How Easy It is to Assemble 1-2-3 Bottom Tray?

The thing that makes it a favorite part of any packaging solution is its easy-to-assemble feature. We have made it even more straightforward with our innovative customization and exact measurements. For further ease of access, the tray parts are labeled with numbers for instance 1, 2, and 3 which will make it convenient to assemble. That numerical arrangement also ensures easy overlap of various parts inside the Kraft box thus making the tray a part of the package itself. At the end make sure that the panels interlock securely to provide a great fit inside the box. For assurance that all the sides are firm together gently press along the edges. That will ensure a stable base for your packaging and the items inside it. Nevertheless, now the tray is ready to hold and protect the item you would put inside.

Design and Material Customization for a Great Impact

Like other packaging solutions, the additional parts and portions of a box also need customization. Without these alterations, the design will not meet perfection. All that starts from the initial design, rough measurements, and material choice to the final output. When it comes to the 1-2-3 Bottom Tray we have to take care of more than one aspect. First of all the material must be firm and stable enough to provide perfect support. If that is not so the product will not be in place and safe. If you are clear about what sort of material is best suitable for your product you are free to choose otherwise we would suggest the best for you. In the same manner, the inner tray can be simple or with company logos and various types of finishes. No matter what sort of finishing you need we will provide it for you. Our aim is always to create a standalone inner tray and box combination.

Purpose and Uses of Bottom Trays

Little is needed after the above detail, however, like us enumerate the main purposes and salient features of these trays. As stated previously the main purpose is to protect the items inside a box and these shall not be free enough to move here and there. That is the main purpose of these trays. Second, these are best to protect the fragile items. No need to mention, that when customers receive an item and find it damaged it will have a bad impact on them. It will automatically embarrass the manufacturer and vendor. End users will remember their service as a poor one. A bottom tray with a well-fixed structure inside the box will save the manufacturer from that embarrassment. All that makes these trays a first-rate choice for the healthcare and gift industry. Even many food items are also transported with that sort of arrangement. In short, a bottom tray is a must-have if you want flawless product delivery and also want to win your customers’ trust.

Q1. What is a bottom tray box?

Bottom tray boxes have a detachable top lid and bottom base.

Q2. What are bottom trays used for?

Bottom trays are used for displaying products on counters. They provide a sturdy base and can be customized for various items.

Q3. What materials are bottom trays typically made of?

They are commonly made of cardboard, paperboard, or corrugated stock. Some specialized trays can be made of plastic.

Q4. Are bottom trays customizable?

Yes, they can be customized in terms of size, shape, printing, and materials to match your product and branding needs.

Q5. What are the benefits of using bottom trays?

A. They offer a stable base for products, enhance product visibility, and provide space for branding and product information.

Q6. What industries use bottom trays?

A. Various industries, including retail, food and beverage, cosmetics, and electronics, utilize bottom trays for packaging and display.

Q7. Where can I buy bottom trays wholesale?

A. Packaging companies like Custom Packaging Pro offer custom and standard bottom trays at wholesale prices.

Description

Bottom Tray

These cardboard trays are good for transporting light loads and fragile items. That makes it one of the most favorite Bottom closure style boxes. Best suitable to provide durable protection to every type of object. These can be of anything from glass, plastic, or sensitive gift items. The structure of the closure type gives it the name as it suggests, there is a bottom tray having two-sided walls and a lid over it that makes it a layered bottom tray. The tray lands in the container that makes two parts of it. One is the container and the other is the lid. You can separate the lid more easily when you want to unpack your packaged material. These aspects make it a great choice for the transit of items that otherwise might get damaged during movement from one place to another. The main purpose is to provide support and assistance to the item inside. It will not move inside the box and will thus be safe from any sort of loss during movement.

How Easy It is to Assemble 1-2-3 Bottom Tray?

The thing that makes it a favorite part of any packaging solution is its easy-to-assemble feature. We have made it even more straightforward with our innovative customization and exact measurements. For further ease of access, the tray parts are labeled with numbers for instance 1, 2, and 3 which will make it convenient to assemble. That numerical arrangement also ensures easy overlap of various parts inside the Kraft box thus making the tray a part of the package itself. At the end make sure that the panels interlock securely to provide a great fit inside the box. For assurance that all the sides are firm together gently press along the edges. That will ensure a stable base for your packaging and the items inside it. Nevertheless, now the tray is ready to hold and protect the item you would put inside.

Design and Material Customization for a Great Impact

Like other packaging solutions, the additional parts and portions of a box also need customization. Without these alterations, the design will not meet perfection. All that starts from the initial design, rough measurements, and material choice to the final output. When it comes to the 1-2-3 Bottom Tray we have to take care of more than one aspect. First of all the material must be firm and stable enough to provide perfect support. If that is not so the product will not be in place and safe. If you are clear about what sort of material is best suitable for your product you are free to choose otherwise we would suggest the best for you. In the same manner, the inner tray can be simple or with company logos and various types of finishes. No matter what sort of finishing you need we will provide it for you. Our aim is always to create a standalone inner tray and box combination.

Purpose and Uses of Bottom Trays

Little is needed after the above detail, however, like us enumerate the main purposes and salient features of these trays. As stated previously the main purpose is to protect the items inside a box and these shall not be free enough to move here and there. That is the main purpose of these trays. Second, these are best to protect the fragile items. No need to mention, that when customers receive an item and find it damaged it will have a bad impact on them. It will automatically embarrass the manufacturer and vendor. End users will remember their service as a poor one. A bottom tray with a well-fixed structure inside the box will save the manufacturer from that embarrassment. All that makes these trays a first-rate choice for the healthcare and gift industry. Even many food items are also transported with that sort of arrangement. In short, a bottom tray is a must-have if you want flawless product delivery and also want to win your customers’ trust.

Q1. What is a bottom tray box?

Bottom tray boxes have a detachable top lid and bottom base.

Q2. What are bottom trays used for?

Bottom trays are used for displaying products on counters. They provide a sturdy base and can be customized for various items.

Q3. What materials are bottom trays typically made of?

They are commonly made of cardboard, paperboard, or corrugated stock. Some specialized trays can be made of plastic.

Q4. Are bottom trays customizable?

Yes, they can be customized in terms of size, shape, printing, and materials to match your product and branding needs.

Q5. What are the benefits of using bottom trays?

A. They offer a stable base for products, enhance product visibility, and provide space for branding and product information.

Q6. What industries use bottom trays?

A. Various industries, including retail, food and beverage, cosmetics, and electronics, utilize bottom trays for packaging and display.

Q7. Where can I buy bottom trays wholesale?

A. Packaging companies like Custom Packaging Pro offer custom and standard bottom trays at wholesale prices.