Cardboard

We use cardboard material with the least environmental impact and minimizes waste generation.

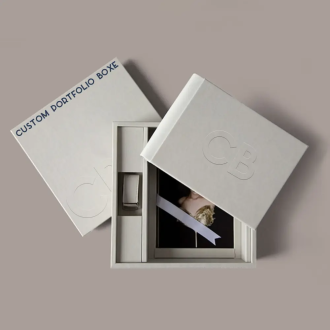

Rigid

Rigid is highly protective, affordable and recyclable material. These boxes provide maximum protection.

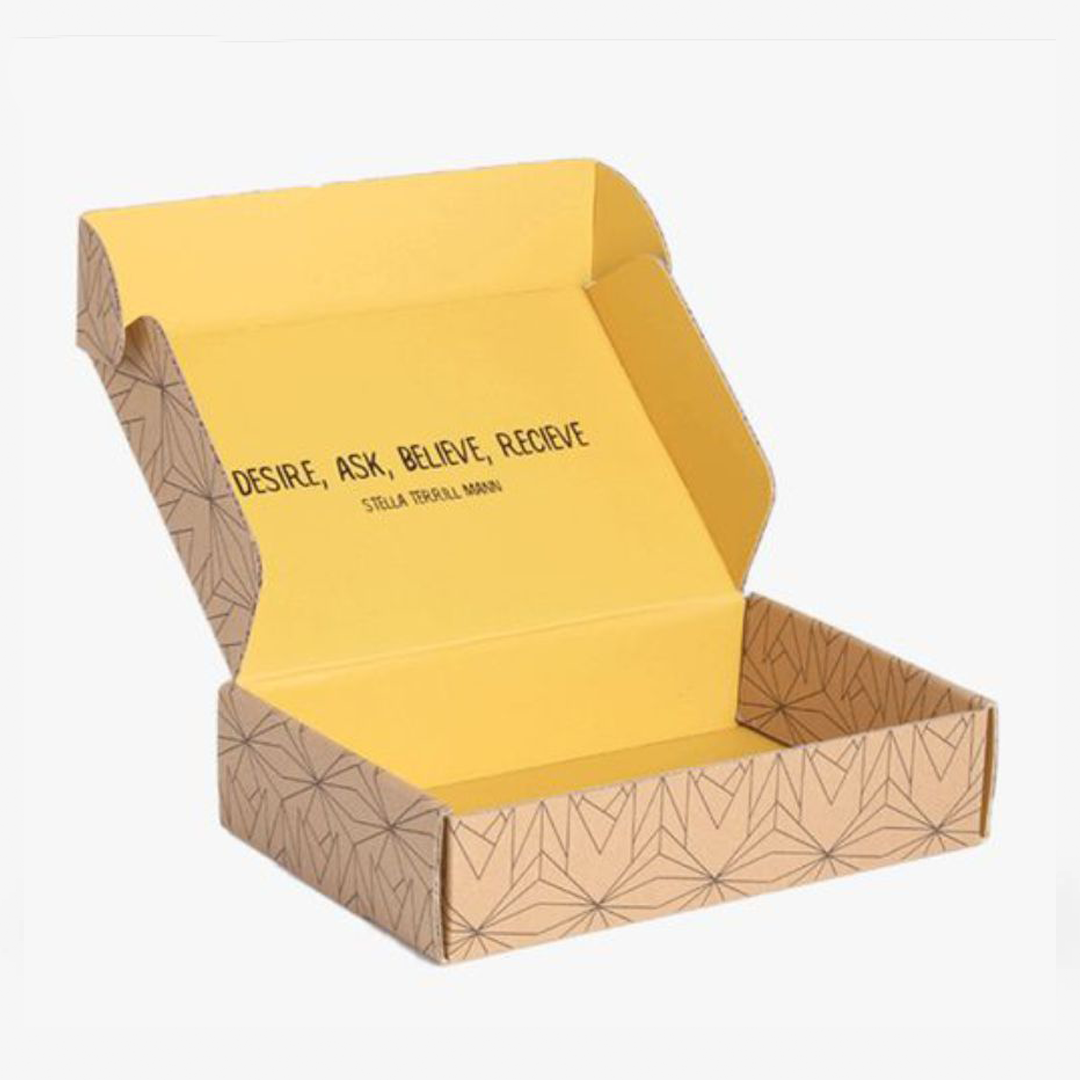

Corrugated

Corrugated material is easy to customize, cost effective and sustainable. It is also great for branding purposes.

Kraft

Kraft paper is a strong, durable and reliable material that is widely used across many different industries.

Description

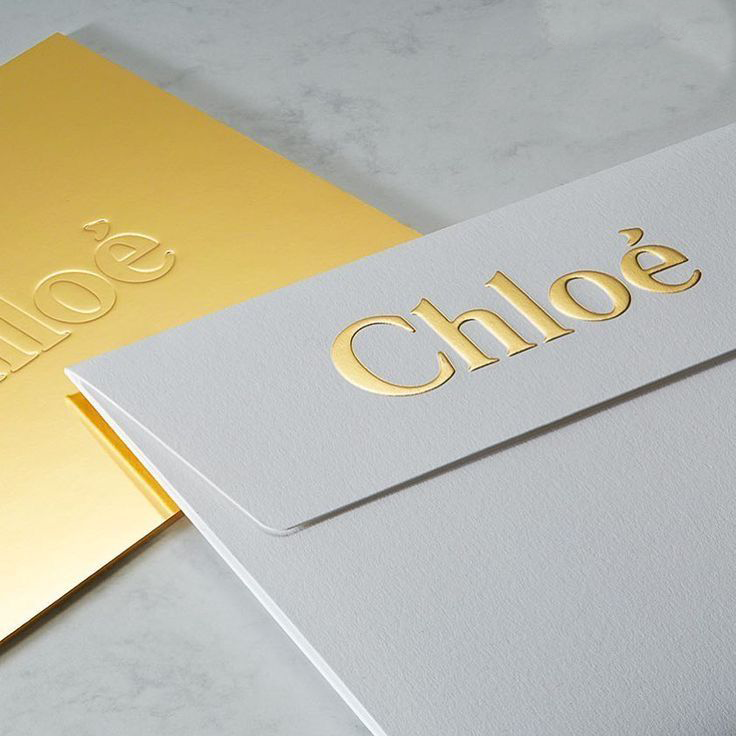

High-End Rigid Packaging for a Lasting Brand Impression

Rigid packaging is not only about protection; it also acts as a silent ambassador of your business. High quality, elegance, solidity, and comfort describe them well. When you present a product, the perception of the brand increases significantly. All that will add to the value of your item automatically. Not limited to that, these let you discover numerous creative opportunities. For instance, you can include magnetic closures, ribbon ties, and many other options according to the product. We can also add inserts, velvet covering, or partitions. Besides improving the product's appearance, all that personalization helps protect a product from mechanical damage during transit and storage. You can enhance the appearance with matte, lamination, UV, emboss, or deboss-like finishing. In the same way, you can play with the shape and style of your set-up boxes.

Try Our Custom Printed Rigid Boxes Tailored to Your Business Theme

Aside from the above personalization, Custom Printed Rigid Boxes are perfect for making a solid impact on your progress. Every business has a specific theme that becomes its identity. When you come to us with a design, our creative team alters it to suit your branding needs. It will include but is not limited to your logo, colors, and message displayed on the Packaging. All that will enhance your appeal to the target consumers. All that makes it a perfect option for luxury goods. In addition to branding messages, top-level printing will also help in clear typography related to product descriptions. If you are an Eco-Friendly brand, you can print quotes related to green solutions.

The above characteristics of Rigid Product Boxes make them a perfect fit for any branding campaign. They are not only the best option for packing purposes but also a strategic weapon in the branding world. Most customers feel privileged to have a product packaged in such a solution, thus enhancing the perception of the brand. We design them so that anyone who is using them to pack their products can have confidence in the quality.

Description

High-End Rigid Packaging for a Lasting Brand Impression

Rigid packaging is not only about protection; it also acts as a silent ambassador of your business. High quality, elegance, solidity, and comfort describe them well. When you present a product, the perception of the brand increases significantly. All that will add to the value of your item automatically. Not limited to that, these let you discover numerous creative opportunities. For instance, you can include magnetic closures, ribbon ties, and many other options according to the product. We can also add inserts, velvet covering, or partitions. Besides improving the product's appearance, all that personalization helps protect a product from mechanical damage during transit and storage. You can enhance the appearance with matte, lamination, UV, emboss, or deboss-like finishing. In the same way, you can play with the shape and style of your set-up boxes.

Try Our Custom Printed Rigid Boxes Tailored to Your Business Theme

Aside from the above personalization, Custom Printed Rigid Boxes are perfect for making a solid impact on your progress. Every business has a specific theme that becomes its identity. When you come to us with a design, our creative team alters it to suit your branding needs. It will include but is not limited to your logo, colors, and message displayed on the Packaging. All that will enhance your appeal to the target consumers. All that makes it a perfect option for luxury goods. In addition to branding messages, top-level printing will also help in clear typography related to product descriptions. If you are an Eco-Friendly brand, you can print quotes related to green solutions.

The above characteristics of Rigid Product Boxes make them a perfect fit for any branding campaign. They are not only the best option for packing purposes but also a strategic weapon in the branding world. Most customers feel privileged to have a product packaged in such a solution, thus enhancing the perception of the brand. We design them so that anyone who is using them to pack their products can have confidence in the quality.