June 11, 2025

What Is Die Cutting? A Complete Guide by Custom Packaging Pro (CPP)

Die cutting is utilized within the printing and packaging business to indicate the cutting out of a variety of shapes by machinery.

With die cut printing, you can define precise dimensions and the machine will cut them to precise dimensions each time.

As you can probably guess, this precision proves to be highly beneficial for product packaging design, where you need to make a regular and professional appearance each and every time.

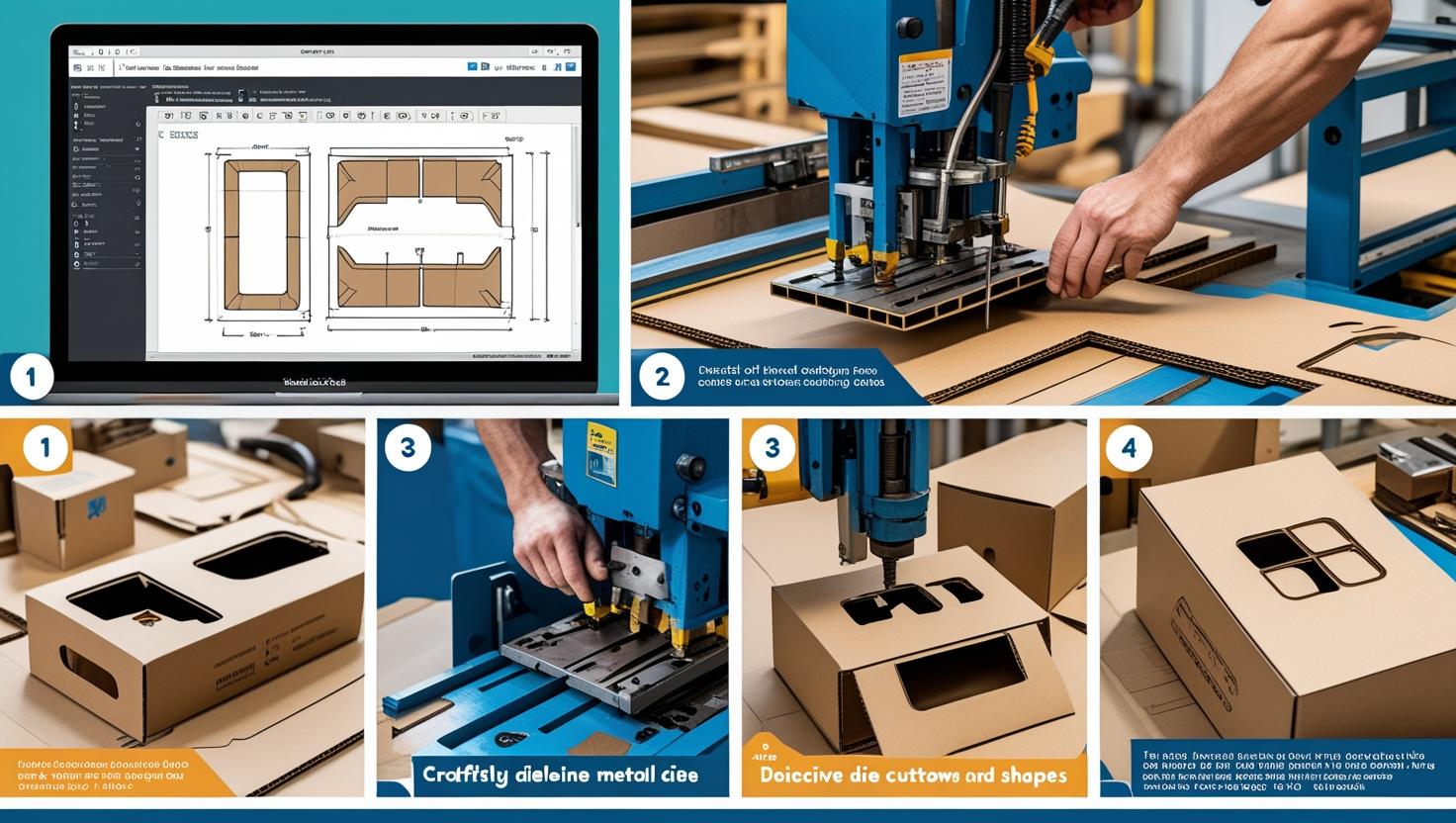

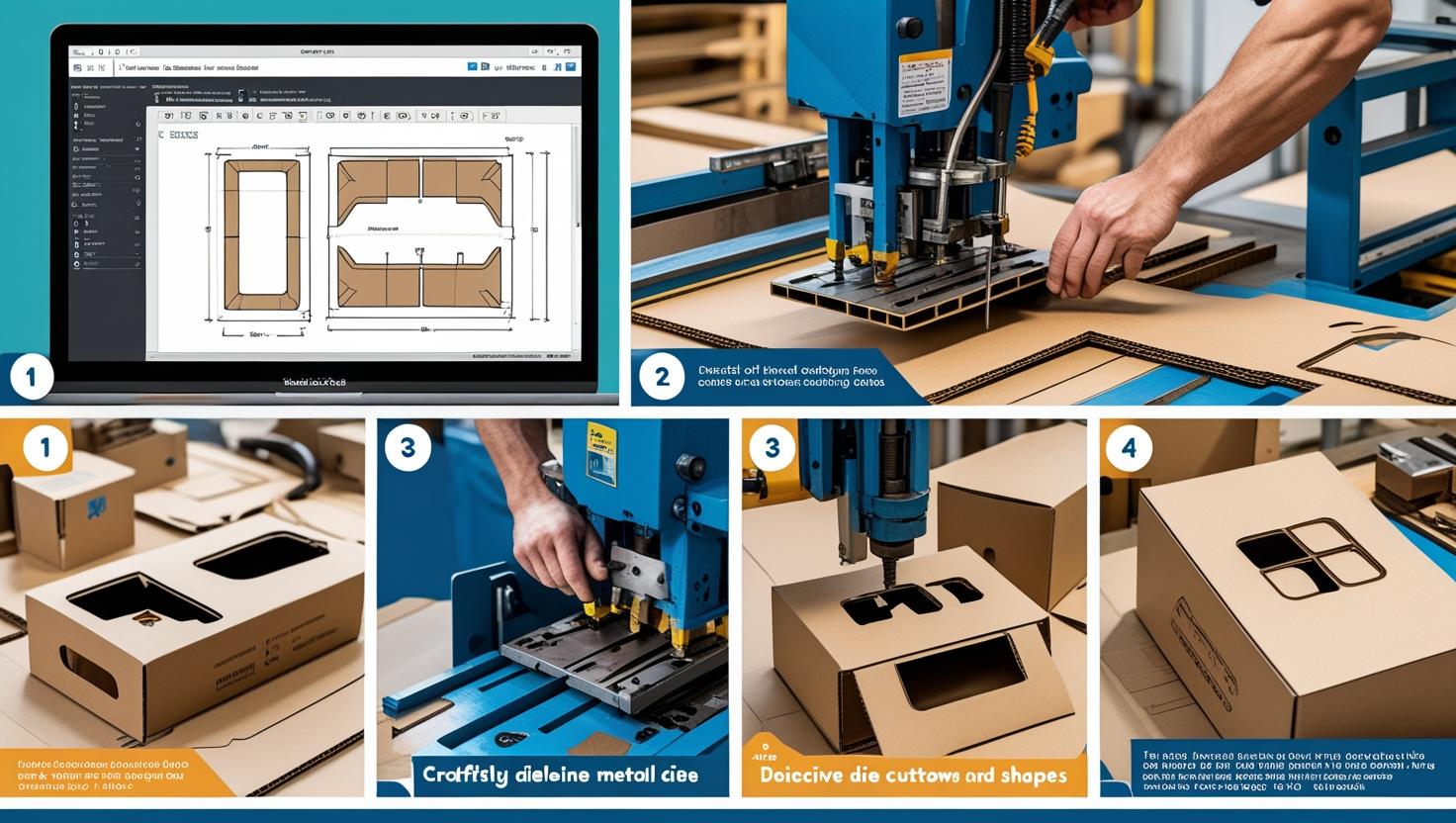

Understanding the Die-Cutting Process

Die cutting is a production process in which a die is personalized by cutting, forming or shearing to make a wanted shape, pattern or design. Die cut printing is utilized in packaging to properly cut, ship and print based on precise measurement specifications, as defined in a dieline.

What Is Die?

Die cuts begin with a die, which is a metal object that has sharp areas for cutting.

The die used in die cutting resembles cookie cutters in that the shape that the metal object is designed will be the same shape that's cut in the material. There are several kinds of dies. For example, steel-rule dies are very sharp but are protected with plastic or foam for safety.

Steel-rule dies are cut to cut thicker packaging material or to cut a stack of less-thick packaging all at once. There are also thinner metal dies, which are not as sharp and cannot cut very thick material. These types of dies are lighter in weight and easier to store, and there is no foam or plastic around them for safety.

Hand-Operated vs. Automated Die Cutting Equipment

The die cutting is done using both manual and computer die cutting machines. Manual die cutting machines have a crank which is pulled in order to cut the material. The metal die goes through the rollers of the machine and utilizes that force in order to aid in cutting the shape from the paper depending on the form of the die. Manual die cutting machines also have motors that assist in exerting this force.

Digital die cutting machines are generally controlled by software. They do not require steel dies because there’s a blade within the machine that cuts the shape. The software is used to select that shape and it can be created via computer, phone, tablet or even a specialized cartridge that the machine uses.

How Die Cutting Got Its Name: A Brief History

The term die cutting has its origins from the 1300s, a term used from the middle English word 'de', thought to have been derived from the Latin word "datum" meaning "given", as well as put or set.

The original meaning of die cutting is to cast or set. In the 1300s, dies were initially used to cast or stamp metal coins.

It was not until the 1800s that mass-producing objects of the same size and shape became a massive movement, and this term of age "die" was used to indicate that it was "made by machines."

Cut is defined as making a custom shape, and die cutting is the casting and cutting of forms.

Die cutting was not widely known as a term until the 1800s, when it was referred to as a way of making more accurate and exact shoe sizes. Because shoes were constructed out of leather, the soles had to be cut manually, which was a long process that was often flawed and resulted in ill-fitting shoes.

When the die cutting machine was invented, this meant that shoes could now have standard sizes (something we often take for granted today).

Why Dielines Matter in Custom Die Cutting

Before you create a die cut on any printed document, you'll want to have a rough outline of what you need to cut first. This is where a dieline enters the custom die cutting process.

Dielines are a component of die cutting print, and serve to define the shape and size of packaging box prior to any cutting taking place.

With so many different shapes possible in the packaging world, if you can dream it, chances are a custom packaging manufacturer can make the material into any cuttable shape.

If you still need to make a dieline, read our guide about what a dieline is to learn more about how to make a dieline for your packaging and printing project. Remember, you’ll need a dieline before you can get to the finishing touches of your packaging like matte and gloss lamination, embossing and debossing or UV coating.

What to Know About Various Die Cutting Techniques

There are several types of die cutting processes, and the choice for your project depends on your specific requirements and the desired outcome for your product. Some of the most common techniques include:

Blanking: This method involves taking flat material and cutting it by trimming from the outer edge, which results in a cleaner, flatter piece.

Drawing: Drawing pulls the material through the die to a set length. It’s typically used for items that are thin and/or elongated.

Forming: Forming shapes the raw material over a curved surface and is often combined with drawing to produce cylindrical parts for custom packaging.

Coining: Coining creates circular holes in the material by applying a concentrated pressurized force, which results in intricate and detailed designs in packaging.

Broaching: Broaching uses several rows of “teeth” to cut through materials that a standard steel die cannot manage.

While many other die cutting methods exist in both digital and offset printing, these are among the most frequently used in packaging production.

Besides these die cutting types, various die cutting services are available based on what you need. For example, flatbed die cutting (also called steel rule die cutting) uses a flatbed press and custom-made dies to create specific shapes. It is perfect for thicker materials, larger packaging components, or smaller production runs.

For larger-scale production, rotary die cutting is used, which employs cylinder-shaped dies to transform flexible materials into custom packaging or boxes. This method is suitable for high-volume runs and designs requiring precise accuracy.

Additionally, there is digital die cutting, which doesn’t rely on physical dies. Instead, it uses lasers, blades, and tooling bits to score, crease, and cut materials. Digital die cutting is ideal for projects needing quick turnaround times while maintaining a high degree of precision.

Is It Possible to Create Your Own Metal Dies?

While you are actually able to create your own metal dies by welding various pieces together, you shouldn't. In this instance, it's better to let the printing and package experts handle the die cutting, as well as die shaping and forming.

If you have an unusual shape in mind for your custom packaging, it’s best to let us create the metal die for it, since this way we can be certain that it will work with our specialized machines.

What Are Cutting Pads or Plates?

Cutting plates, sometimes called cutting pads, form a “die cut sandwich” by layering all the materials and components essential to bring your packaging design to life. This “sandwich” includes the type of packaging, the design, and other elements that ensure the final product looks exactly as you imagined.

You can think of it like using a cookie cutter to shape dough into your desired form, which you then decorate. Die cutting works similarly, employing cutting pads or plates to achieve the precise shape. Over time, these plates or pads experience wear and will need to be replaced.

Want to dive deeper? Our detailed A-to-Z guide on packaging terms is a great resource to help you become familiar with industry jargon as you develop your custom boxes.

Using Die Cutting and More to Create Your Packaging

Die cutting is an incredibly versatile method to precisely cut, shape, and print your packaging, ensuring the final results can be consistently replicated without any errors. Beyond its accuracy, die cutting also offers significant creative freedom for your retail packaging designs.

We understand that not everyone is an expert in packaging and printing. That’s where Refine Packaging comes in—we are experts. We’re more than happy to answer any questions you have about the die cutting process or how it can align with your product packaging goals.

If you have a concept but are unsure how to bring it to life in your packaging, don’t worry. Our talented team of artists and engineers specialize in transforming your ideas into striking, attention-grabbing carton boxes, corrugated boxes, or other custom branded packaging.

We encourage you to reach out for a free quote on our packaging, printing, and design services so we can help you find the best path forward for your unique project. There’s never been a better time to bring your product vision to life than with the skilled professionals at Custom Packaging Pro.

FAQ

Q1. What is a die cut sticker?

A. A die cut sticker is a sticker that is cut into a custom shape using a die, allowing for unique and intricate designs that follow the contours of the artwork.

Q2. What is die cutting?

A. Die cutting is a manufacturing process that uses a die to cut materials into specific shapes, commonly used for producing custom-shaped items like stickers and packaging.

Q3. What are die cut stickers?

A. Die cut stickers are stickers that are precisely cut to the shape of the design or logo, rather than standard geometric shapes.

Q4. What is a cutting die?

A. A cutting die is a specialized tool or template used in the die cutting process to cut materials into particular shapes.

Q5, What is die cut?

A. Die cut refers to the process of cutting materials into specific shapes using a die, or the finished product resulting from this process.

Q6. What does die cut mean?

A. Die cut means the process of cutting a material using a die to create custom shapes or designs.

Q7. How to make die cut stickers?

A. To make die cut stickers, design the sticker using graphic software, print it onto adhesive material, and use a die cutting machine to cut the design into its specific shape.

Q8. What are die cut boxes?

A. Die cut boxes are boxes that have been cut and shaped using a die, allowing for precise and customizable dimensions and features to suit specific packaging needs.

Q9. What is a die cut box?

A. A die cut box is a type of packaging that is shaped using a die, offering customized design options to fit and protect a wide range of products.