May 12, 2025

Mylar vs Rigid Boxes: Which Packaging Style Suits Your Brand?

Picking the proper packaging is becoming significant for companies, particularly for consumer-packaged goods (CPG) brands. Since better Packaging can either enhance or destroy a brand's image, it's critical to determine which packaging suits your requirements.

Mylar and rigid packaging are the most popular types of packaging, but selecting one of the two for your brand can become confusing. Don’t worry, as long as you are here at Custom Packaging Pro. In this blog, we will explore the mylar vs. rigid packaging debate further and assist you in determining which type suits your customer's requirements.

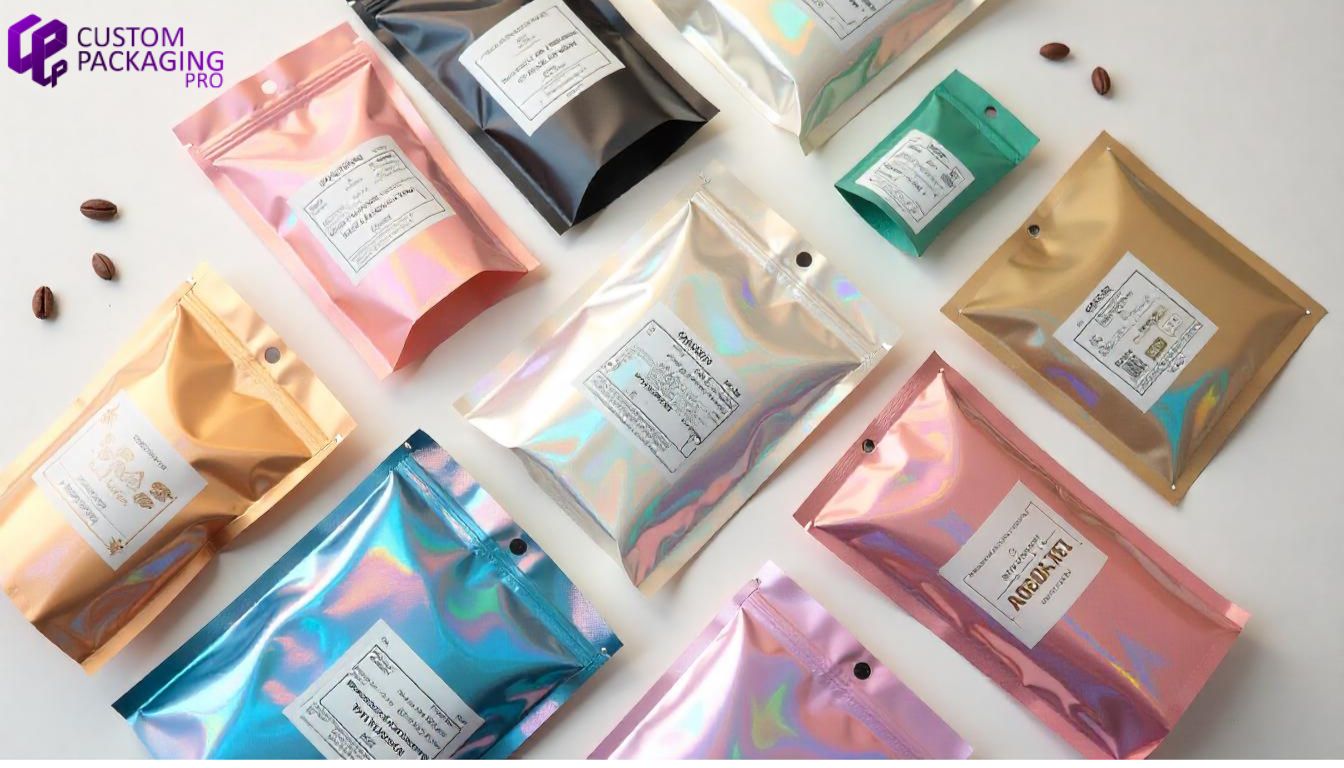

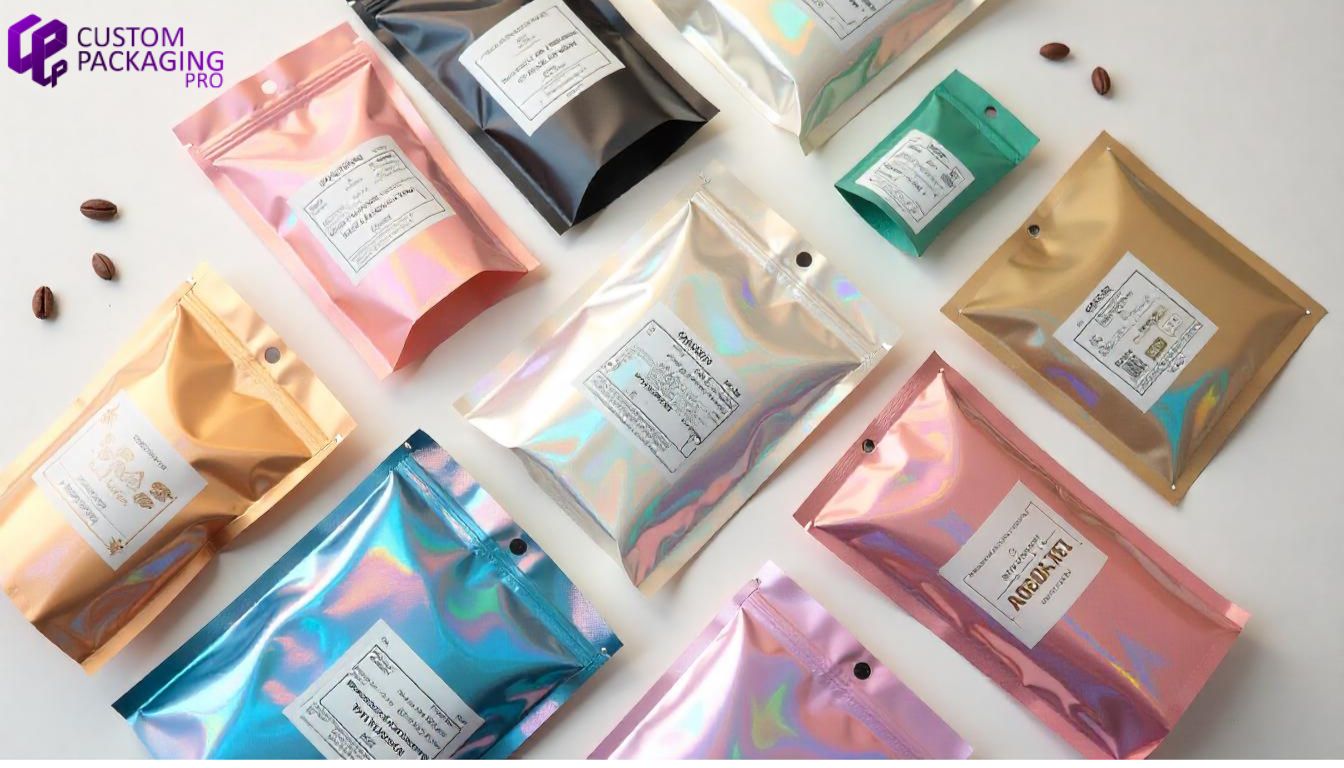

What are mylar bags?

Mylar packaging or mylar bags has a fascinating history. DuPont first employed the trademark Mylar® in 1952 for plastic film packaging. With time, the term "mylar" became widely used for flexible plastic packaging. It is a generic term for high-quality, flexible plastic packaging (PET), which is simply polyethylene terephthalate.

If your buyers prefer lightweight, adaptable, and resilient packaging to preserve products in pristine condition, then Custom-Shaped Mylar Bags are the right choice. They contain a blend of metal and plastic that keeps products fresh. This packaging has been constructed with adverse weather-resistant conditions that safeguard products from moisture, light, oxidation, and air.

Now that you have a basic understanding of mylar packaging, you may be seeking additional information to gain a better understanding of this type of packaging—read on.

How Big Is the Mylar Packaging Market?

Recent packaging statistics indicate the global mylar packaging market value will reach USD 26.1 billion by 2032. Market demand for this material is expected to grow further for companies in all sectors.

Manufacturing Method Of Mylar

Besides market opportunity, another distinguishing feature is comprehending the production process, which will enable you to ascertain the packaging process and price of mylar packaging. The mylar sheeting is processed from PET resin. This is then pulled in a biaxial direction along two axes. Then, the film is united with aluminum foil (mylar reflective sheeting) (low oxygen transmission rate), which emits reflection. In the second step, 200 degrees Fahrenheit heat is given to strong but flexible sheets on high tension to render them smooth, and later, the top portion is closed by a potent heating device like an iron or hair straighteners.

Lastly, you can utilize various printing solutions that cater to customers' requirements to make Mylar packaging attractive. There is a wonderful range of Mylar bags in demand from consumers—take a look at them.

Top 4 Mylar Packaging Styles You Should Know

There are several mylar packaging varieties, but four common ones are needed as they can be employed for different functions. Here is the analysis of four standard varieties:

- Custom Shaped Mylar Bags: They can be employed for grains, dried fruits, vegetables, spices, snacks, and coffee. They incorporate a vacuum seal system that won't allow oxygen and moisture entry.

- Flat bottom pouches: Customize pouches are employed for food as well as non-food products, such as foods like tea, powders, pet foods, cleaning agents, and seeds (mylar bag food storage).

- Child-proof mylar packets: They are constructed with puncture and tear resistance. They prevent children from accessing sensitive products and are generally utilized to package medicines, batteries, detergents, etc.

- Vista mylar stand up bags: These are also stand-up and attractive pouches. Tea spices, herbs, dried flowers, and even precious metal, and ammo are stored in them.

Pros and Cons of Mylar Bags

Mylar packaging has a lot of wonderful advantages, but that does not imply that it is a "perfect" packaging solution. Here is a quick comparison of the advantages and disadvantages of mylar bags to assist you in determining whether they are a suitable solution for your requirements:

Pros

- Mylar packaging is of high barrier properties that maintains the freshness of products. Its barrier property also stops odor from escaping the pouches

- Child-resistant mylars provide a unique airtight closing system that keeps children away from opening sensitive materials like medicines, and detergents (sealable mylar bags).

- Mylar packaging materials adopt ISO-certified packaging procedures. They are recyclable and reusable which environmentally conscious consumers prefer to purchase.

- This packaging extends the shelf life of products, particularly consumable ones for up to over five years

Cons

Mylars are costly since they need a specialized heating system in order to successfully maintain mylar packaging resistant to moisture, air, and light. Plastic used in mylars is not sustainable and not eco-friendly. That is why you need to only use biodegradable mylar bags which will be comparatively costly.

Top Uses Of Mylar Bags

From indoor to outdoor practice, mylar packaging finds diverse applications in different walks of life. Because of this versatility, more and more people are interested in mylar bags, as well as pouches. The following are the places where mylar packaging excel most at:

- Medical Emergencies: Mylar bags are durable, resistant, and convenient. These features make them the best choice to carry essentials in case of emergency, as mylars will exclude light and moisture to shield medicines from contamination.

- Outdoor activities: Zip-lock mylar bags are available for use when camping, hiking, and going on vacation because they are waterproof, windproof, and tear-resistant. You can make your trip and experience unforgettable by keeping essentials safe from extreme weather conditions using mylars.

- Pet Food: Pet food items, such as treats and specialty items, are hard to keep fresh and dry in packaging. However, mylar bags provide protective properties to keep pet food usable for a longer period of time (food storage mylar bags).

- Seeding and Gardening: Mylar bags keep garden seeds fresh and viable for a long time. They act as an effective air and moisture-contaminating barrier to keep seeds and other seeding materials undeterred. Some gardeners even use gold mylar for its reflective properties in grow tents.

What is Rigid Packaging?

Rigid packaging are made up of very rigid and highly durable rigid materials like plastic, paperboard, cardstock, and metal. Products that are packaged inside rigid boxes cannot be flexed. Rigid packaging keeps the product from bending, snapping, curving, or breaking, even if it is extremely fragile.

The rigid packaging is more durable and thus desirable for sensitive products and protects them from bumps and knocks while in transit. Rigid boxes are most often packed with luxury goods and products requiring protection while in transit. Such packaging will be a better choice for those businesses that want high-quality material and good-looking packaging.

How Big Is the Rigid Packaging Market?

There has also been increasing demand for rigid packaging from consumers. It is clear from recent research that the rigid packaging market across the world will probably reach USD 704.24 billion by 2032. With these figures, it's quite obvious that brands opt for rigid packaging rather than the other options available.

Manufacturing Method Of Rigid Boxes

As there are several types of materials used for rigid packaging, the manufacturing processes are different for each material. Here is a brief overview of rigid packaging made from paperboard and cardboard, as it’s the most common rigid packaging you’ll come across.

Rigid boxes consist of an inner base of 2-3mm paperboard and an upper lid covered with specialty paper. Cutting dies are applied to cut the paperboard to a customized size and shape. Then, scoring dies are applied for folding to make a simple inner structure. Next, the lid paper is cut to fit the inside paperboard. Afterwards, the lid and paperboard are bonded together by gluing. After preparing this basic shape, it undergoes fine printing, texture, and finish to provide the rigid box with an expensive feel.

Top 4 Rigid Packaging Types You Should Know

Though numerous types of rigid packaging exist, the three standard types are widely utilized by businesses. Following is a brief summary of three varieties of rigid boxes that are dependent on by businesses:

- Rigid boxes manufactured with cardstock are easily customizable.

- High-end products are packed using hard plastic rigid boxes.

- Metallic rigid packaging is appropriate for packaging products that require maximum protection.

- Glass rigid packaging is particularly suitable for liquids like medicines and perfumes.

Pros & Cons Of Rigid Packaging

Similar to mylar packaging, rigid packaging too has advantages and disadvantages. Let's discuss both:

Pros

- This packaging gives sheer strength to delicate products and prevents products from getting damaged in the transit process.

- It provides a classy visual look to products and gives an excellent unboxing experience to customers.

- Plastic rigid packaging retains food flavors and prevents food products from getting contaminated with dust and bacteria.

- Rigid packaging is produced with recyclable materials like glass and hard plastics so that it can deliver greater sustainability.

Cons

Rigid packaging is expensive to use compared to alternatives like mylar since it is produced with highly strong materials that cost much to manufacture. Shipping rates of rigid packaging are more expensive because rigid packaging is heavier in terms of weight and adds cost to the freight bill.

Top Uses Of Rigid Packaging

Various rigid box types are applied in various industries each with a distinct function. You can refer to each of them to determine what rigid packaging material is right for your clients.

- Food and Beverage: Glass jars, bottles, metal cans, and plastic containers keep food flavor and freshness for quite some time. This is why rigid packaging is an appropriate solution for most high-end food companies.

- Cosmetic and Skincare Products: Hexagon-shaped cardboard safeguards sensitive cosmetic and personal care formulas. Also, it contains luxurious premium packaging at the top of its lid which reinforces your brand positioning.

- Electronics: Rigid boxes are appropriate for electronic devices because of the polyurethane foam filled within them. They possess excellent insulating features that prevent damage and prevent electronic items from becoming a fire hazard.

- Health industry: Cardstock rigid has no toxic materials and is ideal for packaging delicate drugs. The material also possesses a long shelf life, meaning medicines can be kept for a very long period.

Go-To Box Styles in the Industry

When it comes to selecting rigid box styles or mylar bag styles, most brands prefer these popular designs. Take a look at these designs to showcase your brand for your potential buyers:

Popular Rigid Box Styles

- Rigid Shoulder: Showcase your brand with neck exposed and two shoulders style.

- Magnetic Opening: Create luxury touch with sophisticated unboxing magnetic system.

- Rigid Foldable: Provide easy opening and closing experience to your customers.

Popular Mylar Bag Styles

- Pillow Shaped: Give your snacks and chips etc. a neat and aesthetic packing.

- Window: Let your customers inspect the inside content without opening mylar bags.

- Die-Cut: Add value perception to the presentation of your product with die-cut style.

Which is Better: Mylar or Rigid Boxes?

We will make a comparison between rigid and mylar packaging. It will assist you in knowing which package will be ideal for your customers. When it comes to cost, rigid packaging will be costly because of its premium materials compared to mylar packaging. For instance, a tiny rigid box could cost $1-5 dollars whereas mylar packets could cost a few cents.

As far as durability is concerned, rigid packaging takes the lead since it offers better protection. Mylar bags, however, cannot be employed for shipping products. The largest reason why companies employ mylar packaging is that it protects items from moisture. Rigid packaging and mylar packaging materials are recyclable. However, when compared, rigid boxes are more eco-friendly since paperboard and cardboard are biodegradable. Nevertheless, plastic packaging in mylar bags can be recycled only, which is not a very ideal situation for sustainability.

If your customer is more inclined towards luxury and durable boxes, then rigid boxes will be suitable for them. But if buyers desire fresh and unspoiled products for short and long-term use, mylar bags are better.

Customers require different styles and designs according to their preferences. In this regard, you require a packaging type that is more flexible to be customized and specific to your customer's preference. Mylar packaging is quite easy to customize in style and design because of its very flexible plastic material compared to rigid cardboard. Mylar fabric, while not typically used for these bags, showcases the versatility of the material.

Choosing the Right Packaging for Your Product

We have explained and contrasted rigid vs mylar packaging in detail. Both are different and have certain advantages. In case you are wondering which one will do better for your consumer, you will have to balance the advantages since there is no single packaging solution that works for everyone.

If you still require assistance to evaluate better packaging options for your consumers, call us today to receive answers to your queries. We can also give you a free packaging quote to assist you in choosing the packaging most suitable for your requirements! For those needing larger quantities, mylar is often available on a mylar roll.

FAQ

Q1. What is the main difference between Mylar and rigid boxes?

A. Mylar is a flexible, foil-based packaging ideal for lightweight and airtight storage, while rigid boxes are sturdy, premium containers used for high-end product presentation.

Q2. Which is more cost-effective: Mylar or rigid packaging?

A. Mylar packaging is generally more affordable due to lower material and production costs compared to rigid boxes.

Q3. Are rigid boxes better for luxury branding?

A. Yes, rigid boxes offer a premium feel and presentation, making them ideal for luxury or gift-ready products.

Q4. Is Mylar packaging good for long-term storage?

A. Yes, Mylar bags provide excellent moisture, oxygen, and light barriers, making them ideal for preserving freshness.

Q5. Can both Mylar and rigid packaging be customized?

A. Absolutely, both types support full customization in design, size, and branding elements.